Knowledge Base Articles

- BobCAD-CAM V36

- Getting Setup

- Quick Tips & Tricks

- The BobCAD Basics

- Advanced Topics

- Computer Issues

- NC Editor

- Post Processor

- Our Forum

Using the Corner Slowdown Feature

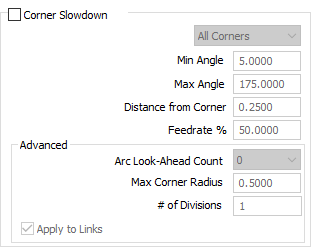

A new feature in V9 is the Corner Slowdown option in our Advanced Feed rate page. This new feature will allow users to break their toolpath into smaller segments and reduce the feed rate in the corners of the toolpath. BobCAD users have many different options in this feature. You have the option to apply this feature in external corners only, internal corners only, or all corners. You can apply a specific minimum angle and maximum angle, a certain distance from the corner, and a desired feed rate percentage.

Understanding How to Setup a Corner Slowdown

Listed below are all the parameters that can be used to define a corner slowdown, and a brief description of their effects on the toolpath.

The minimum angle option determines the minimum angle change difference between two entities to determine whether they should be handled as a corner.

The maximum angle option determines the maximum angle change difference between two entities to determine whether they should be handled as a corner.

The distance from corner option is the distance from the detected corner at which the entity will be broken, and the slower feed rate applied.

Feed rate percentage is the percentage of the cutting feed rate to be applied to the portions that will be slowed down.

Using the Corner Slowdown Feature

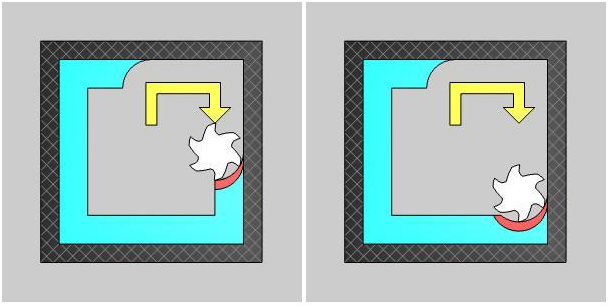

The Corner Slowdown option is available in many operations now including pocket, profile, engraving, chamfer, and corner rounding. You can cut your feed rate to a specified percentage when you approach corners. Many variables need to be taken into consideration, especially ensuring the tool does not engage too much material at the same time. Having the tool engaged in the material too much can easily break a tool. When moving around a part, additional stock is always encountered in the corners.

In the image above, notice how much additional material the tool is engaging in the corner (About 25% of tool engagement on the sides, but about 50% tool engagement in the corners). While you may want to remove material as quickly as possible, scenarios like this have to be accounted for, and until now, that meant having to slow the speed on the rest of the path as well. Now, with the new Corner Slowdown feature, simply specify how close the tool should get to the corner prior to slowing, and the percentage to slow the feed rate down to and you’re done! The toolpath is broken and the feed rate is reduced by the specified percentage.

This feature will even allow you to divide the specified distance into a number of segments so the feed rate gradually drops to the specified feed rate percentage. Now, you can finally set your speeds as fast as you can and focus on slowing down the toolpath in the corners when absolutely necessary.

If you need further assistance, please contact our support team at (727) 489 – 0003 or [email protected]