Knowledge Base Articles

- BobCAD-CAM V36

- Getting Setup

- Quick Tips & Tricks

- The BobCAD Basics

- Advanced Topics

- Computer Issues

- NC Editor

- Post Processor

- Our Forum

Lathe Single Point Threading Calculation

Purpose: To explain how BobCAD-CAM software uses input geometry, and calculates thread height.

Input Geometry

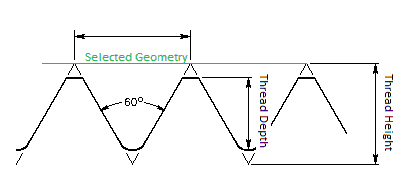

The input geometry you select in the software is used to define the Maximum Triangle Height (See Thread Image)

Application: Let’s say you want to cut a 1”-8 diameter thread. Typically, the selected geometry would be at 1” diameter. However, in real life conditions, you don’t typically start with a 1” diameter to cut a 1” thread, you would start with something that is turned to roughly 0.999” +0.005/-0.100 depending on the fit of the thread.

Thread Height

The Thread Height in the software is simply applied as the full triangle height of a given thread and does not take into account any additional real world parameters.

Due to different thread types and applications requiring different formulas, the software simply uses a standard calculation to apply the entered thread height as the maximum triangle height (See formula below). It is the user’s responsibility to enter a Thread Height value that will result in the appropriate Thread Depth to be created for that specific user application.

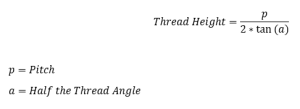

The formula used by the software is:

Eq. 1

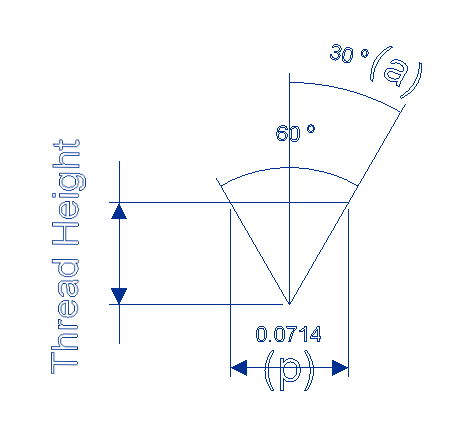

Eq. 1 shows an example of a thread with the value for Pitch and Thread Angle.

Ex. 1 – Finding Thread Height

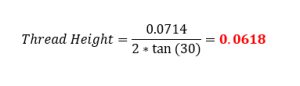

Using Eq. 1 and Ex. 1 we get:

The thread height calculated number as you can see does not factor in all the varieties of thread fit. It is intended to give a generic calculation based on the thread angle and theoretical points. For all the varying thread types and fits, it is very common to have to adjust this thread height to dial it in to your exact requirements for your program.

If you need further assistance, please contact our support team at (727) 489 – 0003 or [email protected]