Knowledge Base Articles

- BobCAD-CAM V36

- Getting Setup

- Quick Tips & Tricks

- The BobCAD Basics

- Advanced Topics

- Computer Issues

- NC Editor

- Post Processor

- Our Forum

Shortening G - Code if Machine has Limited memory

When using a machine that can only read a limited amount of lines of code per program it can be challenging to reduce the number of lines of code while still manufacturing out a part that meets the tolerances in place. Some quick ways to reduce the number of lines of code is to split up the part into multiple programs with the “post yes/no” function, to increase the step over or depth of cut in your operations, or to break up each operation by splitting the depths that each operation will perform.

Step-by-Step

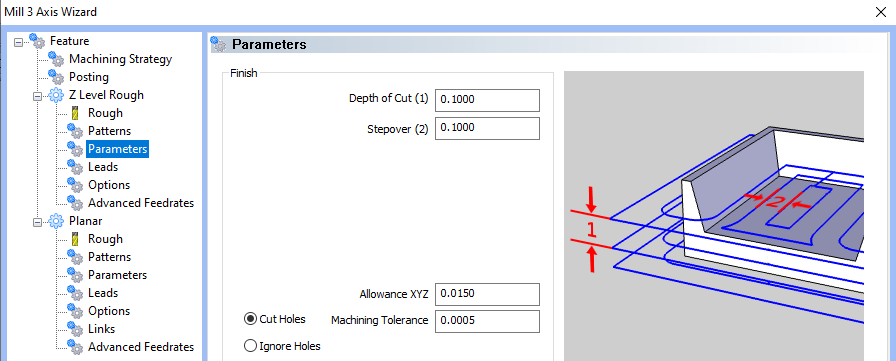

Increasing the Step Over or Depth of Cut

1. Go to the CAM Tree

2. Right click on the feature that you are trying to shorten

3. Left click on “Edit”

4. Click on the CAM Wizard’s parameters page

5. Increase the step over or depth of cut to decrease the number of lines of code that the program will generate, and then hit compute

6. Repost out the program and if needed perform steps 1 though 6 on other features and operations until the controller can handle the number of lines of code that the program is making.

Dividing your part into multiple programs

1. Create all the toolpath needed to cut out the part.

2. Now go to the CAM Tree and right click on the machine setup and hit Post Yes/No (This will set all features to not post or simulate)

3. Then by right clicking on the first feature again and hitting “Post Yes/No”, BobCAD will now know to only post out the first feature when saving out your G-Code.

Note: By doing this method, the part can easily be split up so that each program being sent to the machine only has a few features or operations to make the job more manageable.

4. Continue to Right Click on the second and third feature and hit the “Post Yes/No” button until there is just enough code to send to the machine.

5. For the second program, use the same method as in Steps 4 and 5 but start with the feature that is right after the last feature that was sent to the machine for the specific part.

Splitting the Depths that each Operation will Perform

For especially large parts where even one operation has too many lines of code for a CNC to be able to read, the amount of z axis cutting that an operation will perform can easily be split up into multiple operations.

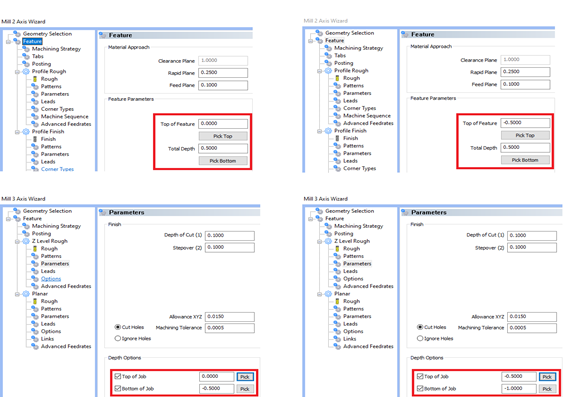

1. While in the CAM Tree, right click on the feature with too much toolpath and hit Edit

2. For any 2 axis milling operation, the depth that the operation will be cutting in can be found in the features page of the CAM Wizard, the top of feature is how high in the z axis that the toolpath will be created to and the depth of cut is how much deeper toolpath will be created based on the initial top of feature. This can be useful by reducing the depth of cut by half the desired amount and then copying this feature and using the final depth of cut as the new top of feature and the remnant depth of cut so that each operation is only a fraction of the original code.

3. For all 3 or more axis milling operations, the depth can be split up in the parameters page into several operations by changing the top and bottom of the job. A picture to illustrate these processes can be seen in the page below.

If you need further assistance, please contact our support team at (727) 489 – 0003 or [email protected]